Synthetic Biology is poised to breath new life into fermentation

Fermentation has been around since the Neolithic age, long before people understood the science behind the process. Today, following the scientific discoveries of French microbiologist Louis Pasteur, who showed how living organisms initiate fermentation, we know why fermentation not only makes food like sourdough bread, kimchi and wine taste better but also plays a key part in the production of food enzymes and other essential food products.

With recent technological advancements allowing scientists to manipulate DNA and produce proteins, precision fermentation is being used in multiple industries. For example, companies are trying out precision fermentation to make milk proteins, egg protein, natural pigments, vitamins, flavoring agents, and many other such products.

What is fermentation?

Fermentation is a metabolic process in which microorganisms, such as bacteria, yeast, or fungi, use sugars to create a desirable change in food & beverages. This change could be to enhance flavor, preserve foodstuffs, or provide health benefits, just to name a few. It is the method used to make many of the fermented foods we find in our homes. However, the fermentation process used to make other ingredients is slightly different, and will be explained in the later part of this article.

One easy-to-understand example would be the use of milk sugars to make yogurt via yeast fermentation. The yeast consumes the lactose sugars in the milk and converts them into lactic acid. The lactic acid allows the milk to thicken while the breaking down of sugars make the yogurt easy to digest.

There are two types of fermentation – “Aerobic” and “Anaerobic” fermentation. Aerobic fermentation requires oxygen while anaerobic fermentation does not. This distinction is important as anaerobic fermentation results in the production of lactic acid (like in yogurt) or alcohol (think beer) whereas aerobic fermentation does not result in these by-products. (You can refer to a detailed explanation about lactic acid and alcohol fermentation at the bottom of this post.)

Fermentation based on the type microorganisms used can also be classified into traditional fermentation, biomass fermentation, and precision fermentation.

Traditional fermentation is the use of microbes found in nature to initiate fermentation process. Some examples of traditional fermentation would be the making of kimchi, yogurt, and tempeh.

Biomass fermentation is the use of fast-growing microbes that produce biomass with high protein, such as fungi-based proteins which are made by companies like Quorn, Meati (Private), Mushlabs (private), and the likes.

Lastly, precision fermentation is an aerobic fermentation process that does not produce any by-products found in anaerobic fermentation. This allows companies to exploit this process to make high value products. Let’s take a deeper look into precision fermentation below.

Introducing 'precision fermentation'! Is precision fermentation the way to better fermentation?

In precision fermentation, microbial hosts are used as “cell factories” to produce specific functional ingredients. This is a rapidly evolving technology area within the agri-food industry. Companies are currently using precision fermentation to produce a variety of ingredients ranging from proteins to preservatives.

Precision fermentation is based on synthetic biology and microbial fermentation. Some examples of well-known companies in this space are DSM (AMS: DSM) and Novozymes (CPH: NZYM-B) which have used precision fermentation to produce food and industrial enzymes for decades.

However, over the last decade, new companies have started utilizing precision fermentation technology to produce milk proteins (Perfect Day (Private)), Egg proteins (The Every Company (Private)), and Heme protein (Impossible foods (Private)).

With the increasing demand for proteins worldwide, newer and more sustainable sources of proteins are required. Precision fermentation is one such technology well-positioned to meet this demand as it allows specific proteins to be expressed with the use of synthetic biology.

Let’s quickly look at what is synthetic biology and how it works.

What is synthetic biology and how does it work?

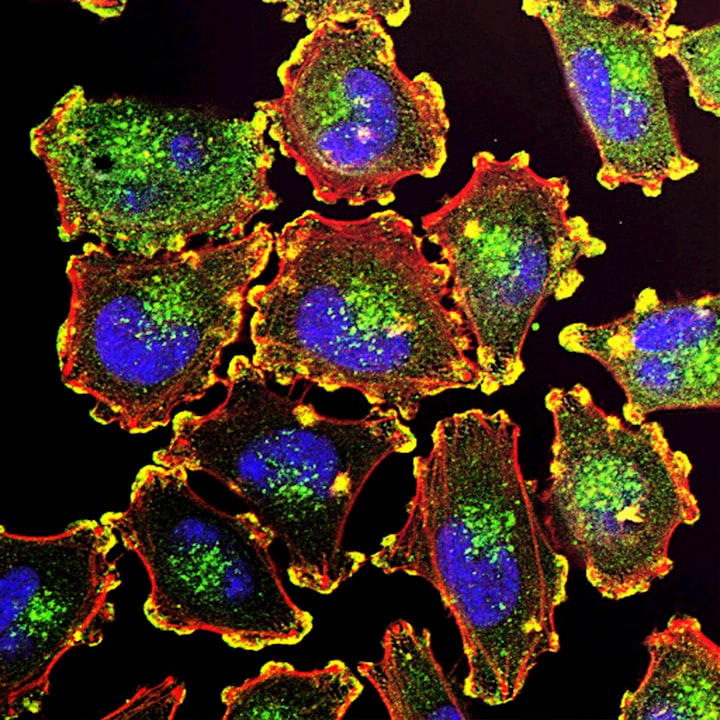

Synthetic biology (or synbio) uses genetic engineering to alter the microorganism's DNA to make the desired target molecules. To achieve this, scientists typically isolate or synthesize the target molecules' DNA sequence and insert them into an organism's genome.

The changes at the DNA level (learn more about DNA here) within the cell result in an altered RNA expression (learn more about RNA here) profile which allows the expression of the desired protein.

Various synthetic biology methods and tools have been developed to promote the design-build-test-learn cycle of cell factory construction, and these technologies are reforming multiple industries.

Learn more here.

Apart from being an alternative protein source, Synbio also carries with it the sustainability tag. For example, synthetic biology can help to reduce the reliance on petroleum-based chemicals which are required in multiple areas, such as the production of synthetic Indigo. Currently, synthetic indigo dyes made from petroleum-derived aniline in a high-temperature process that involves formaldehyde and cyanide. This process can now be replaced by the production of the precursors of indigo via microbial fermentation.

Synthetic biology has also been used to produce other products as well, and some currently available products in the markets made via Synbio and fermentation are squalane, a moisturizer formerly sourced from shark liver, vitamin E, vanillin, and so on.

Overall, it is estimated that the synthetic biology has a total addressable market of over $1 trillion. This market is also likely to grow as more and more companies better understand the metabolic pathways in microbial organisms and exploit them.

Environmental impact of fermentation

Some of the major advantages of using precision fermentation for the production of proteins are: the greater efficiency (more protein per unit of glucose consumed) & lower environmental footprint compared to animal and plant-derived proteins. One research estimated that microbial proteins had approximately 53% lower environmental impact compared to animal and plant-derived proteins (An attributional life cycle assessment of microbial protein production: A case study on using hydrogen-oxidizing bacteria - ScienceDirect)

While there are arguments that fermentation is energy-intensive, it should be noted that the carbon footprint is estimated to be smaller compared to conventional livestock production. The carbon footprint can also be further reduced by using renewable energy sources.

Furthermore, fermentation allows the upcycling of agricultural feedstocks which can provide the glucose required by the microbes to grow. For example, sugarcane molasses, coffee bean waste, milk processing side streams, and other agricultural waste residues can be used to provide the necessary sugars thereby reducing the carbon footprint of the inputs used and allowing greater value extraction from agricultural products.

Apart from agricultural waste, one company has even found a way to carbon capture industrial off-gas (emissions from steel mills, oil refineries, and the likes) and use it as an energy source in fermentation. This would then result in a reduction of the carbon footprint not only due to reduced need for animal-derived proteins but also remove carbon from the environment caused by industrial processes and convert that into a valuable product, creating a net positive for the environment.

Additionally, the greater amount of high valued products produced by precision fermentation and the smaller land footprint compared to their current sourcing methods are two more advantages that are accorded by fermentation.

Overall, with the increasing demand for proteins by individuals and the search for more sustainable manufacturing processes, it has become essential to find newer and more efficient methods to produce proteins & materials. As such we believe precision fermentation might be a key solution to address this demand.

The endless possibilities of synbio

We may have just scratched the surface of the possibilities available to us from Synthetic biology and fermentation. A study by McKinsey sheds some light on the potential use cases. The study found over 400 potential uses for synbio, which were broken down into four main categories: Human health and performance, Agriculture and food, Consumer products and services, & Materials and energy production. It is estimated that if these use cases become a reality, they could have an economic impact of up to $3.6 trillion annually by 2040.

Wrapping it up

Current agriculture and husbandry-dependent food production systems are overwhelmed and unsustainable. The large land use, high water usage, and excessive use of pesticides, fertilizers, growth hormones, and antibiotics are hardly desirable, both from an environmental as well as consumption perspective.

Fermentation together with Synthetic biology would allow us to address these issues and meet the increasing demands in multiple areas. For example, precision fermentation can be used to produce food, such as meat analogs, animal-free milk, and sugar substitutes, from fully renewable resources. Precision fermentation also allows the use of agricultural side streams, allows water reuse, requires limited land, and improves the efficiency of production. Additionally, current well-established manufacturing process of fermented food can also be further improved by advances in synthetic biology.

As such, we believe that precision fermentation together with synthetic biology will fundamentally change our world one day. From beer to food ingredients to cheese making, we’ve barely scratched the surface of what synbio is capable of achieving.

Fun facts & Additional Information

Synbio to the beer rescue!

Ah, the non-alcoholic beer at least!

Often non-alcoholic beer doesn’t taste like conventionally brewed beer. This is mainly due to the loss of volatile hop flavors from de-alcoholization or lack of a full fermentation to extract hop flavors. Most of us can pick out a non-alcoholic beer, but EvodiaBio (private), a bio-industrial company based in Copenhagen, has found a way to return beer’s distinctive flavors and fragrance to the alcohol-free drinks. Now synbio has come to the rescue by genetic engineering yeast, Saccharomyces cerevisiae, to produce small molecules called monoterpenoids. These are the ingredients that provide the hop flavor in conventional beer. By adding them after the brewing process they add back the flavor lost in de-alcoholization or short fermentation. The engineered yeast can help to reduce water usage by over 10,000-fold and CO2 release by 100-fold.

Bridging fermentation and synbio: the future of food?

Apart from alcohol fermentation, the amalgamation of fermentation and synbio might shape the future of food! In the space of plant-based food, craveability is one component of advancing a future of more sustainable food. However, craving a particular food doesn’t mean it’s healthy; in fact, it’s often the exact opposite (think about potato chips, yum!).

Another prominent player at the intersection of plant proteins and precision fermentation is Impossible Foods. The company’s flagship ingredient, soy leghemoglobin, is produced in a genetically engineered Pichia pastorisstrain. Similar to its competitor Beyond Meat, synbio has reshaped the production of soy leghemoglobin.

In the space of flavoring, Conagen (private) engineered strains of microorganisms and novel enzymes to synthesize all sorts of food additives from food colorings, sweeteners, and meat tenderizers, to preservatives.

Synbio has made it possible for the company to opt for alternative ingredients produced by precision fermentation. Compared with other modern engineering disciplines' design process which is more predictable, synthetic biologists have always been tied up with the tedious process of trial and error. In addition, such a process requires a large amount of time while the efforts might not be satisfying. However, with the reduction in the price of producing DNA for gene manipulation, the price of trial and error has greatly reduced and synthetic biology has flourished. The synthetic biology market is estimated to be worth $19.8 million by 2025.

It doesn't take a lot to convince us that synthetic biology will fundamentally change our world one day. From beer to food ingredients to cheese making we’ve barely scratched the surface of what synbio is capable of achieving at the moment.

FAQ

What is Lactic acid fermentation?

Ever wonder why your muscle aches after vigorous exercise (or maybe not so vigorous)? It was once thought that the accumulation of lactate from a process called the lactic acid fermentation in muscles was responsible for soreness caused by exercise, although recent research suggests this is probably not the case.

During vigorous exercise, when muscle cells experience a low oxygen level (too low for aerobic respiration), they will start to carry out lactic acid fermentation. In lactic acid fermentation, NADH transfers its electrons directly to pyruvate, generating lactate as a byproduct. Lactic acid produced in muscle cells is transported through the bloodstream to the liver, where it’s converted back to pyruvate and processed normally in the remaining reactions of cellular respiration.

The bacteria that make yogurt carry out lactic acid fermentation!!

What is Alcoholic fermentation?

Another familiar fermentation process is alcohol fermentation, in which NADH donates its electrons to a derivative of pyruvate, producing ethanol (instead of lactate).

Going from pyruvate to ethanol is a two-step process. In the first step, a two-carbon molecule called acetaldehyde is produced. Only in the second step that ethanol is formed.

Alcohol fermentation by yeast produces the ethanol found in alcoholic drinks like beer and wine. However, alcohol is toxic to yeasts in large quantities (just as it is to humans), which puts an upper limit on the percentage of alcohol in these drinks. Ethanol tolerance of yeast ranges from about 5% to 21%, depending on the yeast strain and environmental conditions

If you like articles like this one, please do subscribe to our newsletter to stay updated with our latest articles.

Disclaimer: All opinions shared in this article are the opinions of the authors and do not constitute financial advice or recommendations to buy or sell. Please consult a financial advisor before you make any financial decisions.

Comments ()